Edit Content

We’ve all seen the EN388 and AS/NZS logos marked on safety gloves and PPE, but what exactly do these icons mean, and what are the standards for resistance?

It’s important to understand safety standards in Australia and how they affect the performance of your safety gloves and PPE. Making educated decisions about what to use for yourself or supply to your staff can help reduce both immediate and long-term injuries.

Read through our guide to Australian glove standards EN388 and AS/NZS 2161.3 as we discuss how the tests are done and what the ratings numbers mean for each type of resistance.

EN388 is one of two major standards used around the world that measures the resistance of safety gloves to various mechanical threats. The other major standard is America’s ANSI, although this is not recognised in nearly as many countries.

EN388 is a European standard, and Australia and New Zealand have adopted EN388 as the basis of our own standard – AS/NZS 2161.3.

EN388 measures resistance to abrasion, blade cut, tear and puncture, and in 2016 was further developed to more accurately measure blade cut resistance (the test now uses a new blade for each pass), and to also measure impact protection. This updated standard is now known as EN388:2016, and was formally adopted in Australia and New Zealand in 2020.

Resistance ratings are measured in various ways and noted in a standardised EN388 icon on safety gloves and their packaging. You will see something like “4 1 2 1 F P” on these icons. It’s important to understand what this means.

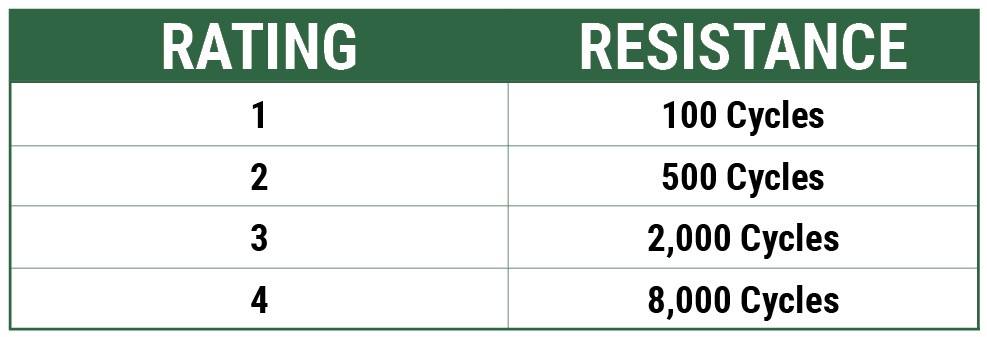

The first number in the EN388 icon represents abrasion resistance. This is measured on a scale of 1 to 4, with 1 being the least resistance and 4 being the most resistance.

There are two cut tests. The second number OR first letter in the EN388 icon represents cut resistance. Measured on a scale of 1 to 5, or with a letter rating from A to F.

The third number in the EN388 icon represents tear resistance. This is measured on a scale of 1 to 4, with 1 being the least resistance and 4 being the most resistance.

The final number in the EN388 icon represents puncture resistance. This is measured on a scale of 1 to 4, with 1 being the least resistance and 4 being the most resistance.

The final letter in the EN388 icon represents impact resistance. This is measured with an F for Fail or a P for Passed. Untested gloves have no letter rating here and do not display an 'X'.

The first number in the EN388 icon represents abrasion resistance. This is measured on a scale of 1 to 4, with 1 being the least resistance and 4 being the most resistance.

Abrasion resistance is tested by subjecting a flat, cut-out portion of the glove to abrasion with sandpaper in an elliptical pattern by a head of fixed size and weight. This action is repeated until a hole is formed in the material.

The number of cycles required to form this hole determines the rating given.

The second number in the EN388 icon represents cut resistance. This is measured on a scale of 1 to 5, with 1 being the least resistance and 5 being the most resistance.

Cut resistance is tested by subjecting a flat, cut-out portion of the glove to a rotating circular blade moving horizontally with a fixed force of 5 Newtons. This action is repeated until the material has been cut through.

The number of cycles required to cut through the material, as well as the wear on the blade, determines the rating given.

This test has been largely replaced by the more accurate TDM Cut test in the EN388:2016 standard. An ‘X’ in the second number position should be followed by a letter from A to F in the fifth position, which means the TDM Cut test has been performed for that glove.

Read below for more information about how the TDM Cut test differs from the Coupe Method.

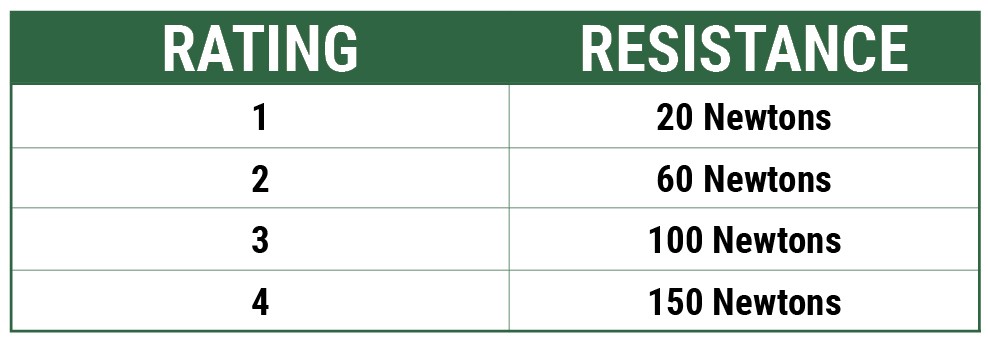

The third number in the EN388 icon represents tear resistance. This is measured on a scale of 1 to 4, with 1 being the least resistance and 4 being the most resistance.

Tear resistance is tested by placing four palm samples separately in a machine that pulls the material at a speed of 100mm per minute. This continues until the samples have been torn.

The force taken to tear the samples determines the rating given, with the lowest result among the samples used for the rating.

The final number in the EN388 icon represents puncture resistance. This is measured on a scale of 1 to 4, with 1 being the least resistance and 4 being the most resistance.

Puncture resistance is tested by subjecting four flat, cut-out palm samples to compression tests in which a 50mm stylus is pushed into the sample at a speed of 100mm per minute. This continues until a puncture has formed.

The force taken to puncture the sample determines the rating given, with the lowest result among four separate tests used for the rating.

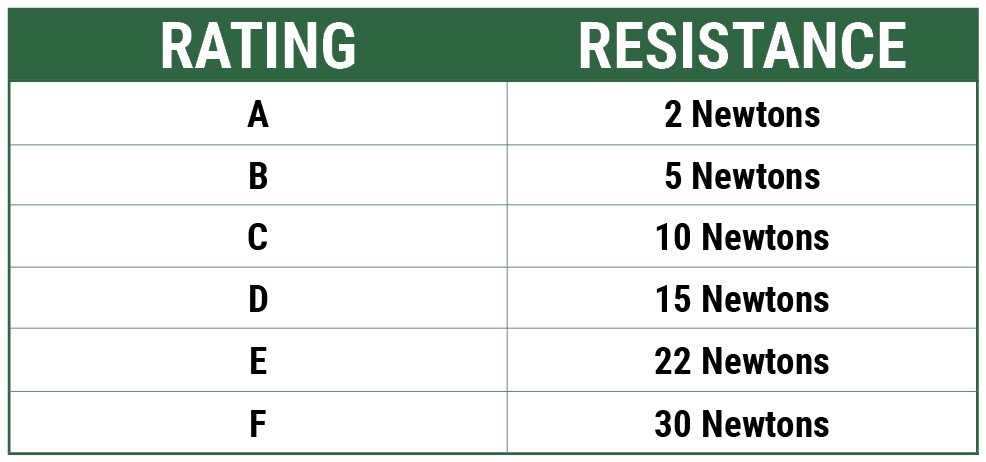

The first letter in the EN388 icon, added in 2016, represents cut resistance. This is more accurate than the cut resistance (coupe) method represented by the second number. This is measured on a scale of A to F, with A being the least resistance and F being the most resistance.

Cut resistance is tested by subjecting flat, cut-out portions of the glove to single blade movements with varying force. Since this test uses a new sample and a new blade for each movement, it does not need to adjust for changes to the sample or blade from previous movements.

The force required to cut through the material determines the rating given.

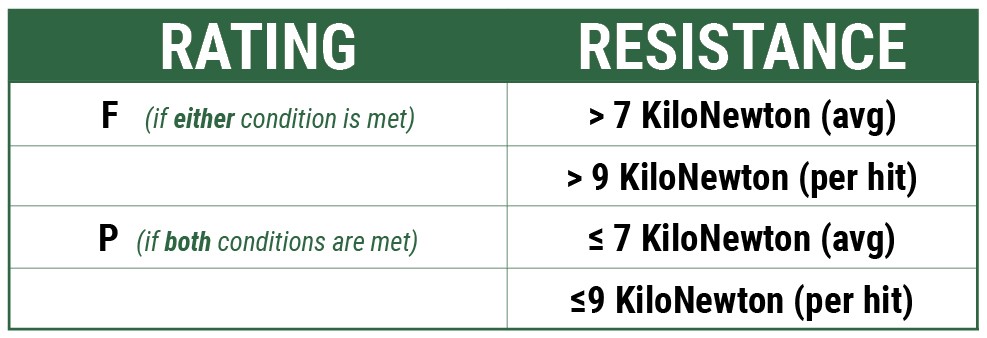

The final letter in the EN388 icon represents impact resistance. This is measured with an F for Fail or a P for Passed.

Impact resistance is tested by subjecting the glove to impact from a 2.5kg striker at an energy of 5 joules. The transmitted force from this hit is then measured. If the force is less than or equal to 9kN (kilonewton) for single hits and less than or equal to 7kN as an average then the glove has Passed.

A Failed or no test result is most often not shown on the EN388 icon.

Your Safety Factory is a Supply Nation-certified, eco-conscious premier supplier of PPE and Safety Supplies throughout Australia.

We supply all kinds of industries with gloves for different applications, protective eyewear and hearing equipment, disposable clothing and other PPE.

If you are looking for a reliable supplier, we’d love to hear from you.

Your Safety factory is proudly 100% Indigenous owned and a Supply Nation Certified business.

Your Safety Factory is a proud Sedex Member, supporting 100% Social Compliance Certification of all supply partners by the world’s leading ethical trade organisation.

Melbourne Head Office & Warehouse

Perth Office & Warehouse

(WA Sales Only)

Your Safety Factory acknowledges and pays its respects to the traditional and continuing custodians of the lands on which we live. We pay our respect to the Elders – past, present and emerging – and their continued cultural and spiritual relationship to the land, waters and community.